As its manufacturing presence expands into new territories, Mercedes-Benz turns to a Geico Taikisha team fully conversant with paintshop best practice globally

Geico-Taikisha has been working with Daimler Benz to develop new paintshop facilities on a greenfield site in Brazil and expanding capacity at an existing Mercedes-Benz plant in India. AMS spoke to Luigi Lazzari, Geico’s senior executive director for Mercedes-Benz projects, to find out how these two significant projects have developed.

Geico-Taikisha has been working with Daimler Benz to develop new paintshop facilities on a greenfield site in Brazil and expanding capacity at an existing Mercedes-Benz plant in India. AMS spoke to Luigi Lazzari, Geico’s senior executive director for Mercedes-Benz projects, to find out how these two significant projects have developed.

These look to be important projects for both Mercedes-Benz and Geico. Can you tell something of what has been involved and how they have progressed?Luigi Lazzari: The project in Brazil involves the development of a paintshop for a new CKD plant, while the one in India is the doubling in capacity, and upgrading, of an existing facility. With Mercedes-Benz, it has been a very good experience for us. They have a very open and transparent culture. Also, of course, it is the first time for Mercedes-Benz – the car division, at least – to build a factory in Brazil. However, we have been working there for the last 25 years, which was quite helpful to smooth the operations.

Geico has been investing heavily in research and in developing its technologies in recent years. Do you think this has been important in attracting customers of the calibre of Mercedes-Benz?Of course. This has been very important. Perhaps, to go back a little, I should explain that, about ten or eleven years ago, our company went through a period of transformation. We re-examined how we worked, developed a new company structure and adopted new strategies, placing a lot of emphasis on technology and learning. We resolved to focus on being technologically competitive, rather than just cost-competitive.

The new strategy required investment and took time to embed, but we are coming to reap the benefits of it now. When customers like Mercedes-Benz come to visit us they can see our strength in developing innovative solutions to their specific needs.

Many suppliers speak about working closely with their customers, about innovation and so on, but how do you make it real and make it happen?We have established what we call Experiment Day, which unlike an ‘open house’ for everyone, is specific for each customer. On this day, we go through our innovative projects with a specific customer, show them the working prototypes and, in the end, go through a brainstorming session with them to see what we could do to adapt our ideas to their needs.

In this way, we develop, together, projects for future paintshops, with the goal of exceeding that specific customers’ expectations.

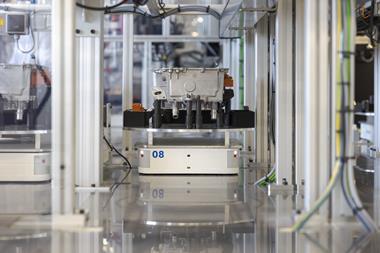

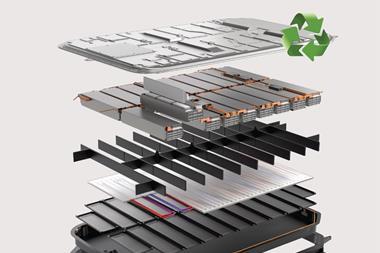

On the projects with Mercedes-Benz, what sort of issues have you faced and what sort of technological innovation have you incorporated?With the Brazil project we were dealing with a new factory. This offers opportunities, but it is a CKD plant operating at quite low volumes. With a low-volume plant it is difficult to achieve good rates of return on investment so, inevitability, there are tight cost constraints on anything you do. However, it is a highly automated plant and we have been able to incorporate some new processes that we cannot disclose due to their confidentiality nature. In addition, we are using a non-phosphate, compact, primerless paint process, so this has involved working closely with partners – material suppliers, paint suppliers – as all these people have to be fully on board to make it work.

Is the project in India a bit more simple or does it present its own distinctive challenges?The Indian project is smaller but not less challenging per se. It is different: an expansion of capacity in an existing plant – but all this has to be done without disrupting production. That requires a lot of planning and careful thought.

Geico has resolved to focus on being technology competitive, rather than just cost competitive

Geico has resolved to focus on being technology competitive, rather than just cost competitiveHow do you manage these projects? Do you have a big local team or do you bring people from Italy. How is it all done?Our alliance with Taikisha and our own network of local partners have boosted our operational capacity. You have to realise that through our alliance and exclusive partners, we have access to more than 50 offices, six manufacturing facilities and more than 1,200 specialised engineers. However, our strategy is not to grow our market share per se – just to increase turnover. Our goal is to expand our presence with technologically driven projects at a global level.

How have you been able to deal with energy and environmental issues in these new projects?These are always among the key concerns of our customers. In Brazil, we are using a new type of spray booth for the first time. It is a new development of our Dry-Car system that brings real benefits in terms of energy reduction and operational effectiveness. For the first time we are incorporating no additional materials in the overspray separation process. Also, we have been able to produce a compact layout that has cost and energy benefit. The paint process is fully automated with no manual intervention between the application of the first paint layer and the curing of the final paint layer. We use a thin film pre-treatment process that involves no heavy metals, while emissions are carefully controlled with solvent concentration downstream of exhausted air. In so far as is possible it is a closed loop system. It really is a state-of-the-art facility.