Supplying the Asia Pacific region ASSAB not only offers a wide range of premium quality tool steels, but also innovative metallurgical and tooling services

Headquartered in Singapore the company has its sales companies and service centres in all of the key industrial markets in Asia Pacific. ASSAB says it is able to provide its customers with engineering solutions from a single site, utilising a comprehensive inventory of tool and special steel, together with a full package of service capabilities. These are supported by a fully computerised order management system, customer relationship management software and radio controlled vehicle fleet; the operations are structured to provide the shortest lead time possible so that customers can meet the demands of the automotive, white goods and electronic industry segments.

Headquartered in Singapore the company has its sales companies and service centres in all of the key industrial markets in Asia Pacific. ASSAB says it is able to provide its customers with engineering solutions from a single site, utilising a comprehensive inventory of tool and special steel, together with a full package of service capabilities. These are supported by a fully computerised order management system, customer relationship management software and radio controlled vehicle fleet; the operations are structured to provide the shortest lead time possible so that customers can meet the demands of the automotive, white goods and electronic industry segments.

This range of complementing services includes machining, heat treatment, tool design consultancy, high-quality coating (PVD), and laboratory and failure analysis. In line with the group’s vision, ASSAB has chosen to lead the way in value added services when it comes to the tooling market. On top of offering high end tool steel from its mill in Sweden, this focus helps customers to focus on their core competencies. As such ASSAB is now offering even more services to help its customers meet more demanding deadlines from their OEMs.

A primary service is surface machining where the tool steel is pre-machined into the most suitable form for the toolmaker. ASSAB says this saves delivery time and money, and also makes handling and preparation much simpler for the toolmaker. The company also has expanded its CNC machining capabilities and can now provide the machining services to key customers for the production of mould inserts, components and fixtures for end-product assembly.

Heat treatmentThe company has always been the leader in heat treatment services in the region and as a result is able to offer a range of thermal processing services. Using state-of-the-art technology, vacuum hardening equipment and processes, ASSAB is able to offer the best-in-class heat treatment to its customers. This process is suited to the bright surface demands of premium single or series production tools, as well as high-quality moulds and dies. Where dimensional stability is a high priority ASSAB recommends its sub-zero treatment. In this process liquid nitrogen is used to expose all or part of the tool to very low temperatures (in the range of -80°C to -196°C). This results in a hardness increase of up to 1 to 2 HRC (Rockwell Hardness measured on C scale).

The ASSAB group also invented what it calls “ABP” (ASSAB Benefit Process). This involves a shot peening process that introduces compressive stress to the material surface to reduce thermal fatigue, heat checking, wear and stress cracks. This is said to improve surface hardness and extend tool life. The company also has key nitriding technologies that comprise of gas nitriding, high-pressure nitriding (performed in vacuum furnaces), plasma nitriding and active screen plasma nitriding, all with a clear goal of enhancing the die and mould life for the users.

For surface coatings ASSAB offers its own PVD (physical vapour deposition) technology utilising both the Alpha series PVD arc coating system and the company’s Duplex coating system, which combines plasma nitriding and a following deposition of ASSAB’s PVD coating. PVD is another service that ASSAB have invested in to extend the die life of tools. This is a key requirement for the automotive industry where there is a growing use of higher strength sheet metal to help reduce vehicle weight. Without an excellent tool steel substrate and the best PVD coating, certain parts can’t be produced cost effectively.Other services include repair/welding services, laboratory services and failure analysis, technical consulting for steel selection plastic tooling design.

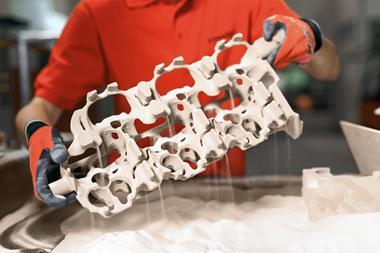

Additive manufacturingASSAB is also investing in the growing additive manufacturing (AM) segment. ASSAB has set up an R&D company in Taiwan to focus on the latest technologies in the region, with AM being at the heart of this. ASSAB will launch its first AM-powder called AM Corrax on Sept 1, which is the first AM-powder developed specifically for tooling applications by its mill, Uddeholm. Uddeholm has applied its experience and expertise in raw materials and metallurgy to develop this innovative technology and by using the best additive manufacturing material available, ASSAB says it is possible to create the customised cooling channels needed for efficient and reliable moulds that optimise production rates. This fine particle powder guarantees a level of polishability needed to meet the high quality surface requirements that characterise demanding applications.

AM Corrax was developed with a specific application in mind; to maximise tool life. Controlling and understanding the quality of the powder is essential in order to achieve the desired mechanical properties of the printed components. Most powders currently available for additive manufacturing are designed to suit the delivery technology and not the other way around. ASSAB is now leading the shift away from this by developing the right metallurgical match for the customer’s final application.

Material knowledge mattersEfficient cooling channels, complex geometries and special internal features are all value-making steps in the supply chain that the company says can be taken to a new level with its AM-powder made for tooling, which will complement the traditional tool making done today. Facing a rapidly changing tooling industry ASSAB notes that it has made several business-enhancing investments in powder production, R&D and 3D-printing in order to expand its tooling expertise. With a new tailored PM-plant and powder laboratory up and running the company has the capability to develop the tool steel solutions to match customer demands.

Access to this AM-powder opens up new ground for innovation, and the creation of new additive manufactured parts with unique material properties. Reliable prototypes and short production runs with a predictable cost and safe result are now a possibility. ASSAB says it understands the challenges faced by its customers and knows their tooling needs and the development of AM Corrax highlights the company’s efforts to deliver moulds and components that offer improved performance and reliability.