James Bakewell looks at the challenges of joining new grades of advanced and ultra-high strength steels in the latest multi-material vehicle structures

The use of advanced high-strength steel (AHSS) and ultra-high-strength steel (UHSS) is predicted to increase over the next few years, particularly in safety-critical areas of vehicles. A recent report from analyst Ducker Worldwide suggests the average light vehicle in the US will feature approximately 259kg of these materials by 2025 – up from 179kg today.

However, with the introduction of new technologies come new challenges. Ranking high among these is that of finding fast, cheap and reliable methods for joining these new grades of steel, both to other grades of steel and to parts made from other materials, such as aluminium and composites.

The relatively rich metallurgies required to generate the desirable mechanical properties of AHSS and UHSS mean OEMs must pay extra attention when welding these grades.

Steelmakers are well aware of the potential for complications and take these into account when developing new materials. According to the team leader for automotive joining technologies and properties at ArcelorMittal Global R&D, Laurent Cretteur, the weldability of new steels is evaluated at laboratory level in the early stages of their development.

“This first assessment allows us to focus product development on grades that will be compatible with OEM processes, even if some adaptations may be required,” he states. “In a second stage, before the new product is launched on the market, a complete weldability validation is performed. If necessary, guidelines are modified to facilitate the use of the new material by our customers.”

In general, Cretteur lists three principal issues associated with the welding of AHSS and UHSS. First, he says, “the mechanical properties of the welds do not increase simultaneously with the increasing strength of the base material. For some specific load cases, welds on AHSS may even be slightly weaker than welds made on medium-strength grades.” While spot welds on mild steel could be considered unbreakable, their comparative weakness on AHSS and UHSS needs to be considered when simulating and validating structures made from these materials. This allows the number and position of welds to be optimised to the needs of a given application. Some adjustments to welding parameters may also be required to increase their strength.

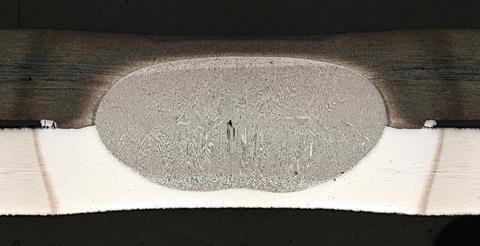

Second, Cretteur says some third-generation grades of AHSS for cold stamping are sensitive to surface cracking defects owing to a phenomenon known as liquid metal embrittlement (LME). LME is caused by the zinc coating present on the surface of many grades of advanced steel, which melts at temperatures above 420°C. Under certain conditions, the resulting liquid zinc rapidly penetrates grain boundaries in the steel and causes embrittlement, resulting in the appearance of cracks on the surface of spot welds.

“Although the presence of surface cracks does not significantly affect weld behaviour, carmakers prefer defect-free parts,” says Cretteur. “The occurrence of surface cracks can be reduced by developing steels that are less sensitive to this issue. Until these grades can be fully commercialised, welding process guidelines have been developed which limit the occurrence of these defects.”

For instance, the occurrence of LME strongly depends on the welding conditions and combinations of steels to be joined (stack-ups). However, as there are only a few stack-ups that induce LME cracking, design rules can be implemented to avoid sensitive combinations.

Finally, these complex stack-ups can cause other issues. Cretteur points-out that the plethora of steel grades now available has led to a corresponding increase in the number of material combinations that might need to be welded. He continues: “Joining three sheets with different thicknesses and physical properties is not rare, but some extreme stack-ups may be difficult to weld due to differences in the physical properties of the grades utilised. Welding parameters need to be optimised to ensure a stable process.”

Wide welding range

When it comes to determining the best method for joining AHSS and UHSS, OEMs have plenty of options to choose from – there are now over 100 types of welding processes available to them, each with their own advantages and disadvantages.

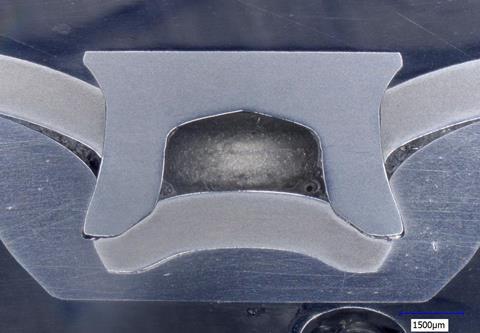

Arc welding processes, for instance, are cheap and the necessary equipment is portable, but they are relatively slow and can rely on high heat inputs to produce a weld. According to the head of high-power welding research and development at Fronius International, Herbert Staufer, high heat inputs can lead to the generation of an undesirably large heat-affected zone (HAZ) – a non-melted area of metal that has experienced changes in its material properties – in the vicinity of the joint. These changes can lead to residual stresses, reduced strength, increased brittleness and decreased resistance to corrosion and/or cracking.

“It is very important to have a small HAZ, otherwise the zone of weakness will be too big and the strength of the joint will be reduced,” stresses Staufer.

Laser welding, on the other hand, generally requires low heat inputs and is capable of fast welding speeds, but the equipment is very expensive and the joint fit-up needs to be perfect. On this point, technology manager at AWL-Techniek, Wouter Zweers, says: “To achieve a steady welding process, it is of utmost importance to clamp the parts stably and reproducibly. At the same time, because of the higher strength of the parts, it is harder to force the parts in the right position in the welding fixture.”

Resistance spot welding (RSW), meanwhile, is ubiquitous in the automotive industry, having been used by carmakers to join metal structures for many decades. A typical vehicle might contain anything between 2,000 and 5,000 spot welds; the process is inexpensive, rapid and easy to automate. “RSW clearly remains the default choice for OEMs,” states Lauren Cretteur. “It is a mature process with an excellent cost/quality ratio. The most recent AHSS on the market are compatible with RSW, although some parameter adaptations are required. For example, different pulsed procedures are recommended when joining some types of AHSS.”

Further examples of changes that need to be made to the RSW process when joining such grades are provided by steel-maker SSAB. When joining its Docol AHSS and UHSS, it says, the electrode force must be increased, and welding times need to be longer than when joining soft, deep-drawing steel grades. For welding zinc-coated variants, both the welding time and welding current need to be increased. Furthermore, the company recommends the use of domed electrode tips as these reduce the electrode force required in comparison with flat tips, and cope better with zinc-coated grades.

Cretteur continues: “The widespread availability of more flexible spot-welding machines allows OEMs to easily adapt welding parameters to the specifications of the stack to be joined on the assembly line. Introducing AHSS doesn’t oblige the OEM to completely change their way of working.”

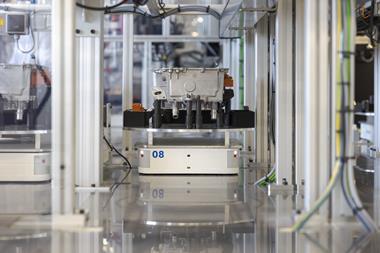

To achieve these goals, manufacturers are investing heavily in automated adaptive control systems that enable welding parameters to be altered, automatically and in real time, to ensure high-quality welds are produced. The systems can measure the current and voltage generated at the electrode. Data from the weld can be stored and made available for analysis. The current can then be adjusted to compensate for differences as welding proceeds.

Rivets, screws and adhesives

Of course, these potential challenges are not limited to joining steels to other grades of steel. The automotive industry has adopted a diverse range of other materials, including aluminium and composites, in its quest to produce lightweight vehicle structures. Neither can be bonded with steel using conventional welding processes.

According to Cretteur, mechanical methods for joining steel and aluminium have come on in leaps and bounds in recent years. “The first generation of rivets and screws were limited to low hardness metals,” he explains. “In recent years, a huge effort has been made by OEMs, tool suppliers, and material suppliers to innovate and extend the range of mechanical joining applications. Many solutions are now appearing on the market. Some of them are already capable of joining [ArcelorMittal’s UHSS] Usibor 1500 to aluminium.”

Zweers says these mechanical methods can be combined with adhesives to reap the benefits of both approaches: “The adhesive joining provides a continuous joint, which is good for stiffness, and the mechanical joining keeps the joint together until the adhesive is cured and prevents it from creeping.”

The thermal joining to steel and aluminium is difficult owing to a brittle intermetallic phase that forms between the two and has a negative effect on the mechanical properties of the bond. However, Staufer says that with a modified gas metal arc welding system, developed by Fronius, called cold metal transfer (CMT), it is now possible to join zinc-coated steel with type 6000 and type 5000 aluminium alloys.

A key benefit of the process is that it reduces heat input significantly. Using CMT, a weld wire and a shielding gas are fed through a welding torch, and electricity arcs between the filler wire and the welding surface, causing the tip of the weld wire to liquefy with the aluminium base material and wet the steel. When the filler metal dips into the weld pool, the arc is extinguished and the welding current is lowered. The filler wire is retracted constantly at very short intervals during the short circuit, facilitating the detachment of droplets in a controlled manner to give a clean, spatter-free material transfer. The wire motion is reversed and the process begins all over again, leading to the production of strong welds using a fraction of the energy of conventional welding.

Staufer continues: “For future applications, the new Cycle Step process variant for the CMT welding process allows users to set both the number of individual droplets and the pause time between cycles. The result is a heat-reduced bead with clear ripples and a high degree of reproducibility. It has a wide range of future AHSS applications—from visible weld seams and additive applications to fixation points.”

Mixed materials challenge

It is currently impossible to join steel with most composites using welding processes. Mechanical attachments, such as clips and screws, can be used with virtually any surface, but they require additional steps to mould or create features in the composite for the attachment. This can lead to stress concentrations, which may result in the plastic matrix of the composite cracking, causing premature failures. Also, drilling holes in composites can lower their strength due to the introduction of discontinuities in the matrix and reinforcing fibres. Furthermore, the mechanical joining methods can increase weight of a structure and often result in a poorer aesthetic finish.

The use of adhesives typically adds less weight to a structure than mechanical fastenings, and they can distribute stress along the entire length of bonds formed with them rather than creating stress concentrations. There are other advantages; structural adhesives can prevent the galvanic corrosion that occurs at the interface between bare metals and CFRPs; and bonded joints have a cleaner look than those formed by mechanical means. However, adhesives are somewhat distrusted in certain sectors of the automotive industry, and their use can require a significant rejig of a production line.

With a little tinkering, AHSS and UHSS grades can be welded together quickly and cheaply, and effective methods for joining these metals with other materials are maturing nicely. So what about the future? Laser welding is growing in popularity, but according Zweers the future of steel joining will be one of evolution rather than revolution. “We see no radical new joining technologies being developed, but existing joining technologies will get more advanced,” he says. “Welding equipment will get new features that improve controllability. Methods for the monitoring of the weld quality are growing in importance, as is the implementation of methods to enhance traceability.”

No comments yet